|

半导体 提供卓越精度和佳性能的精密解决方案

Semiconductor Solutions -

Precision Solutions for Superior Accuracy and Optimal Performance

晶圆制造Wafer Fabrication

精度是半导体制造中的一切,因为即使小的变化也会对功能产生重大影响。世界上先进的微处理器是在使用Deublin的机器上制造的。

Precision is everything in semiconductor manufacturing, because even the smallest variations can have a big impact on functionality. The world's most sophisticated microprocessors are made on machines that use Deublin.

|

|

Ingot Production

铸锭生产

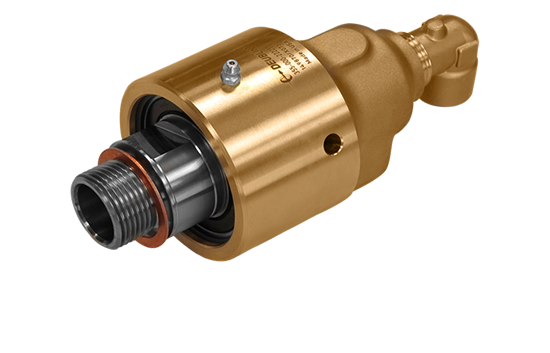

半导体从加热到1420°C的熔融硅坩埚开始。Deublin接头冷却拉杆,拉杆的旋转方向与坩埚的旋转方向相反。拉杆末端的晶种从熔体中缓慢提起,随着时间的流逝,铸锭直径可达300毫米,长2米。Semiconductors begin in a crucible of molten silicon, heated 1420°C. A Deublin union cools the puller rod, which rotates in the opposite direction from the crucible. A seed crystal at the end of the puller rod lifts slowly from the melt, resulting over time in an ingot up to 300mm in diameter by 2 meters long.

|

Slicing

切片

圆柱形或矩形的铸锭通过金刚石涂层的线锯切成均匀的薄片。Deublin联轴节冷却导轮,以保持切割顺畅和笔直。The cylindrical or rectangular ingot is sliced into uniform wafers by a diamond-coated wire saw. Deublin unions cool the guide rollers that keep the cut smooth and straight.

|

|

|

Grinding

打磨

切片后,将晶片研磨以去除锯痕和表面缺陷,并使晶片达到终厚度。Deublin空气联结器可确保在加工过程中均匀地清除毛坯,而Deublin水联结器可保持磨削表面凉爽。After slicing, the wafer is ground to remove saw marks and surface defects, and to bring the wafer to final thickness. Deublin air unions ensure uniform stock removal during the process, and Deublin water unions keep the grinding surface cool.

|

Polishing

抛光

终抛光去除了晶片表面上任何残留的微观缺陷,并在将要制成芯片的一侧进行了镜面抛光。Deublin活接头控制抛光过程的压力和温度。Final polishing removes any remaining microscopic defects in the wafer surface, and imparts a mirror finish on the side that will be made into chips. Deublin unions control the pressure and temperature of the polishing process.

|

Circuitry Creation电子芯片制造

从手中的手机到家中的可编程恒温器,世界取决于芯片。这些芯片的制造商取决于Deublin的质量和可靠性。

From the mobile phone in your hand to the programmable thermostat in your home, the world depends on chips. The makers of those chips depend on Deublin quality and reliability.

|

|

ECD

电化学沉积

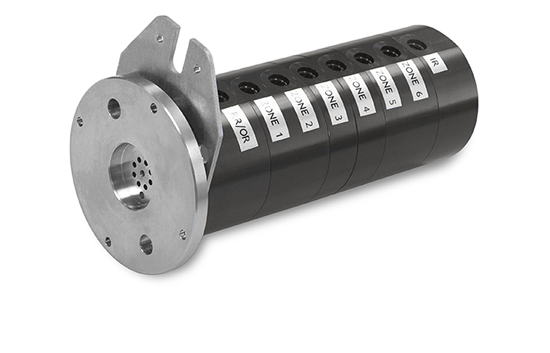

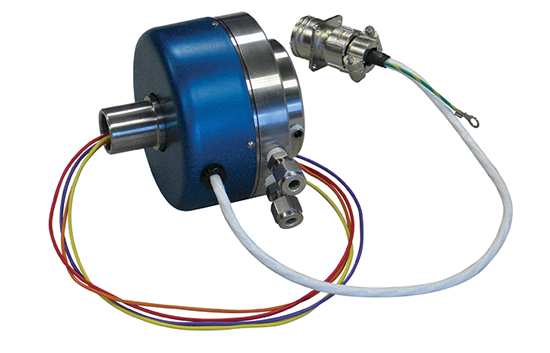

电化学沉积是将化学流体中的金属原子沉积在晶片表面上的过程。Deublin接头将晶片固定在适当的位置,而Deublin滑环传输成功沉积所需的电流和电压。Electro-Chemical Deposition is a process by which metal atoms from a chemical fluid are deposited on the wafer surface. Deublin unions hold the wafer in position, and Deublin slip rings transmit the current and voltage necessary for successful deposition.

|

ALD

原子层沉积

原子层沉积使Deublin的客户能够制造导电或绝缘材料的薄膜,并在纳米级结构中实现均匀覆盖。Atomic Layer Deposition enables Deublin customers to fabricate thin films of either conducting or insulating material with uniform coverage in nanometer-sized structures. |

|

|

CVD

化学气相沉积

化学气相沉积法将纳米厚度的电介质和金属材料膜沉积在晶片上。此过程在极高的温度(800-2000°C)下发生,需要Deublin联轴器冷却设备并保持过程稳定性。

Chemical Vapor Deposition places nanometer-thick films of dielectric and metalmaterials on a wafer. This process occurs at extremely high temperatures (800.2000°C), requiring Deublin unions to cool the equipment and to maintainprocess stability. |

Ion Implant

离子注入

在芯片制造期间多次使用离子注入来形成晶体管。在离子注入过程中,晶片被称为掺杂剂的带电离子束轰击,该离子改变了裸露表面的电性能。lon implantation is used many times during chip fabrication to form transistors.During ion implantation, wafers are bombarded by a beam of electricallycharged ions, called dopants, that change the electrical properties of theexposed surface.

|

|

|

CMP

化学机械抛光

化学机械平面化可产生均匀平坦的晶圆表面,以准备沉积额外的材料层,这些材料终成为终微处理器,存储芯片,LED和其他产品的电路。Chemical Vapor Deposition places nanometer-thick films of dielectric and metal materials on a wafer. This process occurs at extremely high temperatures (800-2000°C), requiring Deublin unions to cool the equipment and to maintain process stability. |

Process Control

过程控制

Deublin接头在精细校准的晶圆制造设备中产生热稳定性。Deublin电子滑环为设备内置的计量系统供电并从中返回数据。Deublin unions create thermal stability in finely calibrated wafer fabrication equipment. Deublin electrical slip rings provide power to and return data from metrology systems built in to the equipment. |

|

|

卷对卷 R2R

卷对卷处理将金属薄层沉积到柔性基板上,以制造太阳能电池板,薄膜电池和柔性电子产品。旋转接头调节温度并消散高温沉积过程中的热量。Roll-to-Roll processing deposits thin layers of metal onto flexible substrates to create solar panels, thin-film batteries and flexible electronics. Rotary unions regulate temperature and dissipate heat from the high-temperature deposition process. |

|

|

|

1-Channel

单通道

这些紧凑型旋转接头设计用于失速调节的风力涡轮机,风力涡轮机通常具有1 MW或更小的功率输出。These compact rotary unions are designed for stall-regulated wind turbines, which most often have a power output of 1 MW or less. |

2-Channel

双通道

变桨调节型风力涡轮机要求在数百万次循环中保持可靠性。Deublin旋转接头具有耐用性,可显着减少陆上和海上作业的停机时间和维护成本。Pitch-regulated wind turbines demand reliability over millions of cycles. Deublin rotary unions include durability features that significantly reduce downtime and maintenance costs for both on- and off-shore operations.

|

|

|

3-Channel

三通道

所有Deublin风力发电机组均已在运行压力下进行了100%出厂测试,以确保每个风力发电机组在收到并准备安装后即可完全正常运行。All Deublin wind unions are 100% factory tested under operating pressures to ensure that each union is completely operational upon receipt and ready to install. |

4-Channel

四通道

用于风能的Deublin旋转接头采用了专有的受控泄漏密封技术。Deublin rotary unions for wind energy employ a proprietary, controlled leakage sealing technology.

|

信德迈科技(北京)有限公司专业提供美国杜博林Deublin多通道旋转接头、导电滑环应用于半导体工业和化学机械抛光机CMP。

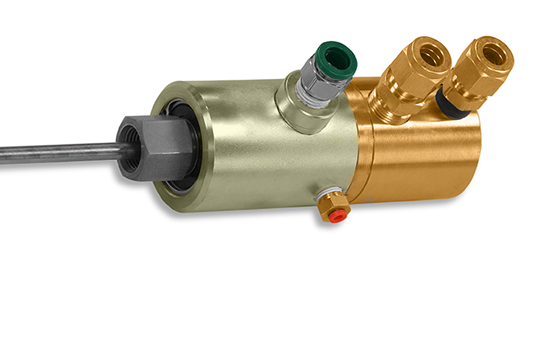

化学机械抛光机CMP 技术和设备产品配套旋转接头。可广泛应用于IC制造、TSV/3D封装、MEMS、晶圆、基片等制造领域。

- 规格参数:6通道旋转接头,介质:空气和去离子水。欢迎咨询、联系和采购 010-8428 2935,13910962635。

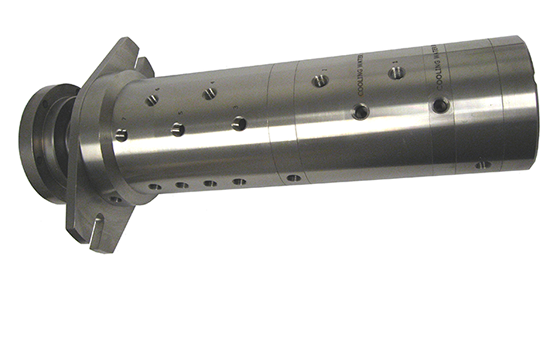

Deublin rotary union Semiconductor industry: Physical Vapor Deposition (PVD), wafer processing or Chemical Mechanical Planarization (CMP) operations.

- 可广泛应用于IC制造、TSV/3D封装、MEMS、晶圆、基片等制造领域。化学机械抛光机CMP 技术和设备产品配套旋转接头。

- 规格参数:6和8通道旋转接头、导电滑环组合接头。

- 介质:空气和去离子水

- 物理气象沉积 PVD应用旋转接头

规格参数:16通道冷却旋转接头

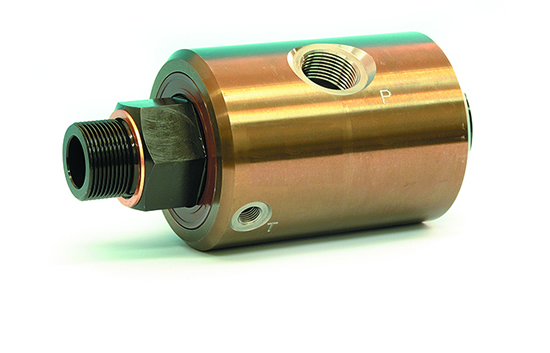

- 芯片处理旋转接头

规格参数:机械密封+软密封

650RPM,间歇运行

空气,真空和硅浆

不锈钢壳体

无内部泄露

- 第一、二、三代半导体的区别在哪里?

- 半导体薄膜沉积工艺

- 刻蚀、薄膜沉积和离子注入工艺

- 在集成电路制造产业链中,CMP设备在硅片制造、集成电路制造、封装测试三大环节均有应用,其中集成电路制造是CMP设备应用最主要的场景

- ECD Electrical Chemical Deposition 电化学沉积技术在集成电路行业的应用

- 12月2日晚间,美国《联邦公报》最新文件显示,美国工业和安全局 (BIS) 修订了《出口管理条例》(EAR),将 140个中国半导体行业相关实体添加到“实体清单”。

- 美日严控,半导体阀门断供,涨价!突发! 美日严控,半导体阀门断供,涨价!日本芯片设备及零部件禁运令升级,半导体阀门行业受冲击引发连锁反应。

- SEMICON China 2025 - 全部展商名单

- 中国自产 EUV 机器将于 2025 年第三季度进入试生产,采用更简单、更高效的设计方法

- 2025 年 3 月 26 日,上海新国际博览中心仿佛被注入了一股来自未来的科技力量,瞬间被半导体行业的创新热浪点燃!SEMICON China,作为全球规模最大的半导体盛会 ,无疑是科技领域的 “超级碗”,今年更是火力全开,首次突破 10 万平方米展区,吸引了 1400 + 展商齐聚一堂,共同带来一场前沿技术与产品的超级盛宴。这场 “芯” 风暴可不只是简单的展会,它正以雷霆万钧之势改写着全球半导体的格局,成为了行业发展的超级引擎!

- 半导体行业蓬勃发展,Deublin杜博林旋转接头和滑环迎来机遇。为国内客户提供高端半导体装备元器件,助力芯片制造商。

- 面向“十五五”,我国半导体装备产业面临技术封锁与供应链脱钩的双重挑战,需从“追赶替代”转向“路径创新”,突破对国际技术体系的依赖。文章分析了三大核心需求:支撑自立自强(突破先进制程装备与零部件瓶颈)、构建中国特色创新生态(探索GAA、3D集成等新技术路径)、推动智能化升级(融合AI与数字化技术)。同时,提出以“再全球化”策略应对逆全球化,通过内循环与国际双循环协同,重塑全球半导体产业链。当前,国产装备在成熟制程取得突破,但高端领域仍被美国、日本、欧洲垄断,且面临低水平重复竞争、供应链“卡脖子”等问题。建议通过系统性科技攻关、上下游协同创新,避免内卷,聚焦非对称技术优势,实现从自主可控到自立自强的跨越。

- 国内市场已给出清晰答案:中微公司在介质刻蚀领域的尖端突破、北方华创在全链条设备上的平台优势、屹唐半导体作为后起之秀的 快速 拓展,共同勾勒出国产刻蚀设备的 “ 梯队成长 ” 格局。它们的竞争与协作,既在回应成熟制程扩产的规模化需求,也在攻坚 5nm 以下先进制程、原子层刻蚀等技术高地。

- 美国半导体产业版图分享: 近年来,美国围绕半导体产业展开了史上最大规模的产业重构,从政策补贴到地方引入晶圆厂,再到巨头企业扩建研发中心,美国的半导体产业版图正在发生深刻变化。本文将从州和区域维度,系统梳理美国半导体产业的空间布局与功能分工,揭示其如何构建全国性的半导体产业网络。

|