Deublin FSU STEAM JOINT/DELTASINT STATIONARY SIPHON SYSTEM

Deublin FSU系列蒸汽旋转接头和虹吸系统

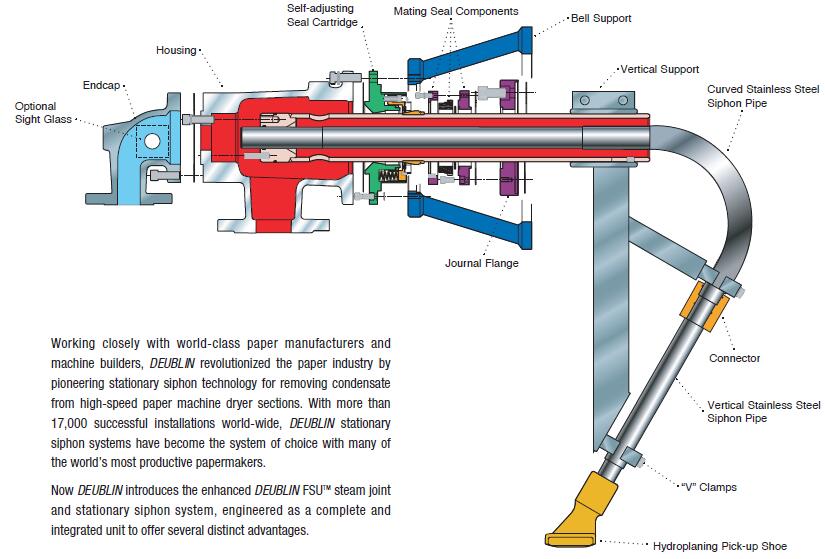

Working closely with world-class paper manufacturers and machine builders, DEUBLIN revolutionized the paper industry by pioneering stationary siphon technology for removing condensate from high-speed paper machine dryer sections. With more than 17,000 successful installations world-wide, DEUBLIN stationary siphon systems have become the system of choice with many of the world’s most productive papermakers.

Now DEUBLIN introduces the enhanced DEUBLIN FSUTM steam joint and stationary siphon system, engineered as a complete and integrated unit to offer several distinct advantages.

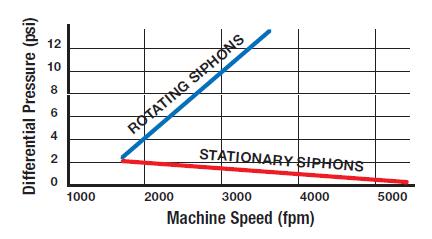

? Immune to centrifugal force effects

Unlike a rotating siphon, a stationary siphon is not affected by the centrifugal force of the rotating dryer. It will remove condensate even at a differential pressure of less than 2 psi, without risking dryer flooding.

? Improved heat profile control for better product quality

Picking and related problems can be a result of high differential pressures. When the dryer’s surface is too hot for the moisture content of the sheet, it flashes – then picks, drags and flutters out of control. Eliminating the need for high differential pressure enables better control of dryer surface temperature by adjusting the steam pressure to match the drying cycle of the different paper grades. The FSU System restores control of dryer heat profile and product quality across a wide range of paper grades.

? Improved moisture profile

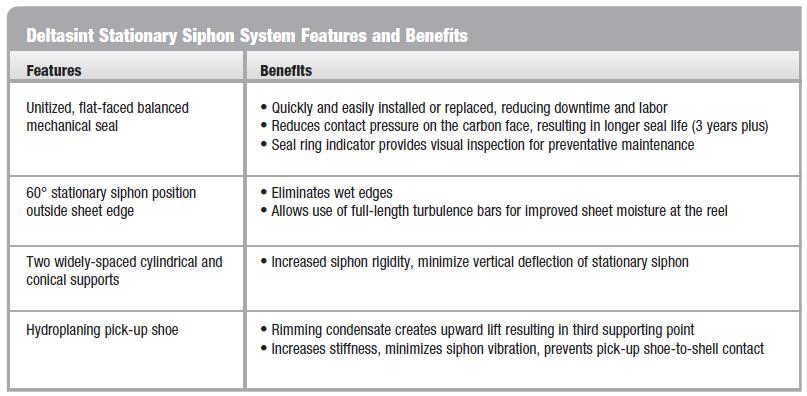

The FSU has a standard 60° siphon configuration that places the siphon outside the sheet edge, eliminating edge profile problems by improving the dryer temperature profile. Stubborn moisture problems are typically cured by removing the front-end siphon, installing turbulence bars and replacing the backside siphon with a dual flow FSU system.

? Eliminates “start-up” with flooded dryers

Because the FSU stationary system is fixed in the 6 o’clock position, dryer flooding caused by improper positioning of rotary siphons is eliminated.

? Unitized, flat-faced balanced mechanical seal

Designed for quick and easy installation or replacement to reduce downtime, the balanced mechanical seal extends seal life up to three years or more by reducing contact pressure on the carbon face. A seal ring wear indicator enables visual inspection to cue preventive maintenance.

? Rigid, stable support system

Two widely-spaced cylindrical and conical supports comprise a firm cantilever design with increased rigidity to minimize vertical deflection.

? Hydroplaning pick-up shoe

The unique shoe design prevents shoe-to-shell contact by hydroplaning on the rimming condensate, maintaining close clearance for effective condensate removal at any speed. The hydroplaning action also produces upward pressure that acts as a third support point and reduces vibration.

? No moving parts

Simple, robust design extends operating time and reduces

maintenance.

? Keep pace with increasing machine speeds

With rotating siphons, higher speeds demand higher differential pressure, which produces more blow-through steam, resulting in higher bi-phase velocity. This increases wear and premature failure of the condensate hardware. The DEUBLIN FSU stationary siphon system solves the problem!

|