|

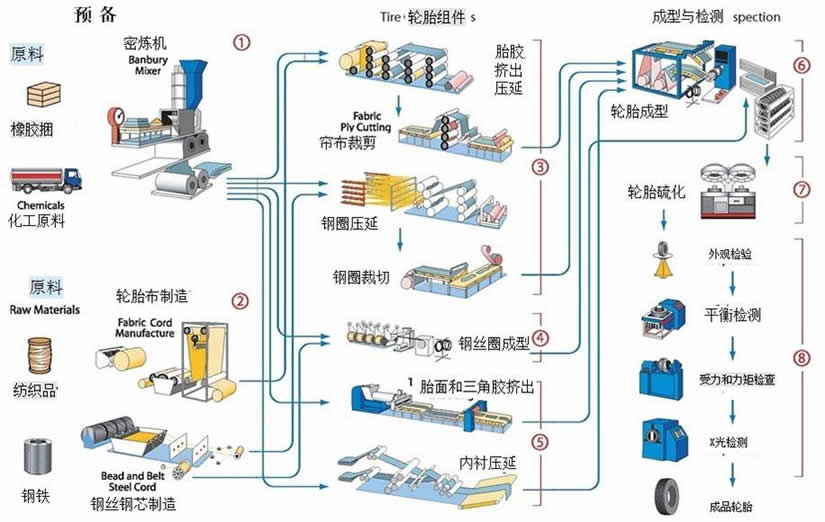

美国Deublin杜博林旋转接头轮胎橡胶工业应用

Plastic manufacturing - better quality and performance through expertise in (and with) rotating unions.

塑料制造-通过旋转接头的专业知识提高质量和性能

塑料材料的制造包括各种各样的应用,包括流延膜、吹塑膜、泡沫、柔性和刚性片材挤出、单层和多层共挤、吹塑、热成型、造粒、线缆、注塑和卷绕。Deublin旋转活接头用于水和热油服务,用于加热或冷却各种应用中的许多加工辊。此外,Deublin旋转接头用于空气和液压服务是用于缠绕和注射成型应用。今天的许多现代绕组应用也将使用导电滑环。The manufacturing of plastic materials encompasses a wide variety of applications including cast film, blown film, foam, flexible and rigid sheet extrusion, single and multi-layer co-extrusion, blow molding, thermoforming, pelletizing, wire and cable, injection molding and winding. Deublin rotating unions for water and thermal oil service are used for heating or cooling the many processing rolls throughout the wide variety of applications. In addition, Deublin rotating unions for air and hydraulic service are used in winding and injection molding applications. Many of todays modern winding applications will also utilize Deublin electrical slip rings.

Example 1: Rubber products

橡胶行业

从汽车制造到医疗技术:型材、管子、包层、环带和许多其他部件都是由橡胶化合物制成的。这些混合物是由经过优化的配方组成的,尤其是为了达到这个目的,尽管大多数外行人将其简单地定义为“橡胶”。From vehicle manufacturing to medical technology: Profiles, tubes, cladding, ring belts and many more components are made of rubber compounds. These mixtures are composed of optimised formulation especially for the purpose, although most laypeople would simply define them as “rubber”.

.除了基本配方外,挤出机的机械技术还负责橡胶产品的形状,尤其是最稳定的质量。虽然形状与使用的工具相符,但质量实际上取决于挤出机的“内部质量”。因此,为挤出机制造商工作的工程师始终关注挤出机技术,以便随着进一步的发展积极影响质量。As well as the basic formulation, the machine technology of the extruder is responsible for the form and in particular for the most consistent quality possible of the rubber products. While the form conforms to the tools being used, the quality effectively depends on the “inner qualities” of an extruder. The engineers working for extruder manufacturers therefore always focus on the extruder technology, in order to positively influence quality with further developments

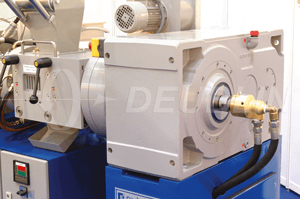

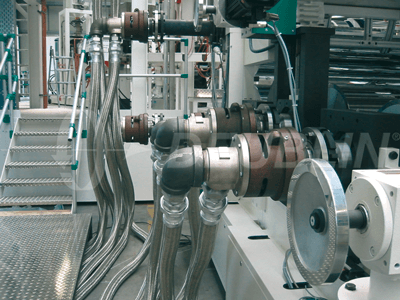

Drehdurchführung an ExtruderFor clarification, a cold-feed pin-type extruder should be used for this purpose.The necessary temperature conditioning of the extruder screw is carried out using a rotating union. This temperature conditioning is state of the art and a general prerequisite for maintaining technical parameters.

However, development engineers want to do more to improve the quality and reproducibility of their production results and the concept of tempering further machine components has been adopted.

This is how a temperature conditioning process for the top and bottom rotors of the gear pump using an additional rotating union has been implemented. The gear pump, as such, already has benefits in terms of more equal output and constant dimensional accuracy, because a material feed just before the die (tool) is much more effective than simply feeding it over the extruder screw. Additionally, tempering the pump enables a better portioning of the rubber mixture and at the same time increases the mixture quality. 这就是如何使用附加旋转接头对齿轮泵顶部和底部转子进行温度调节的过程。因此,齿轮泵在输出更均匀和尺寸精度恒定方面已经有了好处,因为在模具(工具)之前的材料进料比简单地通过挤出机螺杆进料更有效。此外,对泵进行回火可以更好地分配橡胶混合物,同时提高混合物的质量。

kurze bauform

当然,热必须应用于正在被挤压的热塑性材料,但在挤压机中有一个位置,在这个位置上,较低的温度有一个有趣的更好的效果:进料辊。While it is a matter of course that heat must be applied to the thermoplastic materials that are being extruded, there is a position in the extruder whereby cooler temperatures have an interestingly better effect: the feed roller.

更冷、更稳定的股线可以更好地喂入,并且可以更一致地喂入挤出机。Cooler, more stable strands can be fed in better and can be more consistently fed into the extruder.

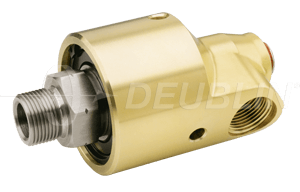

通过使用更小、更紧凑的旋转接头,这一想法得以实现。结果表明,该材料的入口特性明显改善。这种技术方法甚至可以使进料滚柱上的滚针或圆柱滚子轴承冷却,进一步优化。This idea was made into reality with the use of smaller, more compact rotating unions. The results show that the entry characteristics of the material were significantly improved. This technical approach could even enable the needle or cylinder roller bearings on the feed roller to be cooled, with further potential for optimisation.

lange bauform

Example 2: Plastic films

塑料薄膜

Regardless of the current discussion about the “plastic planet” film, according to which our planet, by now, could be wrapped several times in plastic, packaging film will remain essential to packaging for the foreseeable future.

However, the development of increasingly thinner films is encouraged among manufacturers, in order to conserve resources, yield more from the same input of raw materials and produce more in the same amount of time.

These development trends have an effect on machine technology, because bigger machines are being used and/or machine speeds are being increased.

folienwickelmaschine卷膜

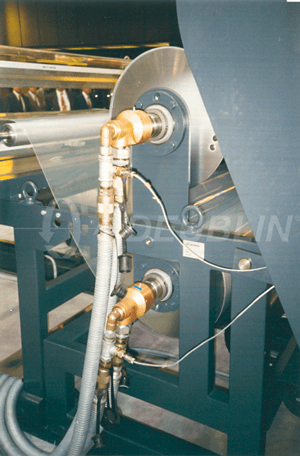

在薄膜制造过程中,通常在原料撕裂前,使用滚轴和拉伸器将其拉伸至物理极限。用于此过程的滚轴使用导热油或热水等传热介质加热,以暂时增加塑料中分子结构内的熵。这降低了它的稳定性,热塑性变形性被用来拉伸结构,旋转接头被用来将所需数量的传热介质转移到辊上。它们起着连接固定进料管/软管和旋转滚筒的作用。由于每小时都有大量的介质流过滚筒,因此人们希望保持或提高成品的质量。只有当“机器作为一个整体”以极高的精度运行时,才有可能做到这一点。因此,这也适用于机器部件,如旋转接头,因为工作参数-介质、压力、温度和转速-总是影响使用寿命,德布林等品牌制造商正在不断开发用于塑料机械的旋转接头,因此,有短而紧凑的设计、单流和多流设计以及不锈钢旋转接头的版本。所有产品均标配可靠、低磨损的机械密封。During film manufacturing, the raw material is very generally stretched using rollers and stretchers to its physical limit, just before it tears.The rollers used for this process are heated using heat transfer media such as thermal oil or hot water, in order to temporarily increase the entropy within the molecular structure in the plastic. This reduces its stability and the thermoplastic deformability is used to stretch the structure.Rotating unions are used to transfer the required quantity of heat transfer medium to the roller. They function as a link between the stationary feed pipes/hoses and the rotating roller.As well as the significant volume of media flowing through the rollers each hour, there is a desire for the quality of the finished product to be maintained or improved.This can only be possible if the “machine as a whole” operates with tremendous accuracy. Therefore, this also applies to the machine components such as the rotating unions, because the operating parameters - medium, pressure, temperature and rotational speed - always affect the service life.For this reason, brand manufacturers such as DEUBLIN are continuously further developing the rotating unions used in plastic machines.Consequently, there are versions with a short, compact design, monoflow and multiflow designs and rotating unions made from stainless steel. All of these products are equipped with reliable and low-wear mechanical seals as standard.

Kalander

Example 3: Calenders or coating and laminating

砑光机或涂层和层压

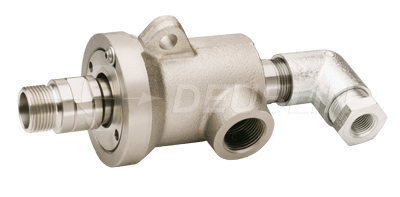

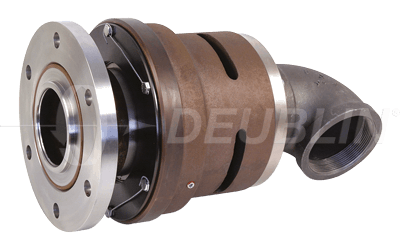

压延机和用于涂层和层压的机器经常在非常高的温度下使用,需要特殊的热介质旋转接头。经验表明,以前和现在,在某种程度上,旋转接头是通过适配器和螺钉连接到供应线的。这些连接复杂、耗时,在安装和维护过程中往往需要大量的努力。此外,即使由经验丰富的合格人员安装,它们仍然极易发生故障;由于轴承或滑环的早期损坏,可能在以后的某个时间点发生损坏,从而缩短旋转接头的使用寿命。Calenders and machines for coating and laminating are frequently used at very high temperatures and require special hot media rotating unions.Experience has shown that previously and, to some extent, nowadays, rotating unions were connected to the supply line using adaptors and screws. These connections are complex, time consuming and often require a great deal of exertion during installation and maintenance. Moreover, they remain extremely fault-prone, even if they are installed by experienced and qualified personnel; damage may occur at a later point as a result of earlier damage to bearings or slip rings, resulting in a reduced life span of the rotating union.

在适应过程中,流量区域被压缩,导致加热器输出减少和压力损失增加。随着SAE法兰的开发和随后的使用,这个问题已经成为过去,因为连接点现在有了一个新的简单设计。四个螺丝、一个O形圈和一个法兰稳稳地接管到供应线和旋转接头的连接,一个内六角键足以作为完成安装的工具。这种设计使安装和维护成本大大降低,因为供应线可以在最短的时间内无张力连接。也可以在不需要大量工具的情况下进行拆卸,从而减少机器停机时间,并为操作人员带来明确的成本优势。由于压力弹簧,例如,位于介质之外。这就是滚柱或压延机如何通过旋转接头不断向传热介质提供正确的体积流量的方法。压力损失和热量输出不再发生。根据使用的系列,这种热介质旋转接头显示出稳定的轴承设计和以膜形式的二次密封,因此在密封点处没有相对运动。此外,为了提高机器安全性,可订购带有外壳和转子锁环以及附加卡环的型号,作为“紧急安全锁销”。It has also been demonstrated that during adaption processes, the flow area is constricted, leading to a reduced heater output and an increased loss of pressure.drehdurchführung mit flanschWith the development and consequent use of an SAE flange, this problem is a thing of the past, as the connection points now have a new and simple design. Four screws, one O-ring and a flange steady take over the connection to the supply line and rotating union and an inner hexagonal key suffices as a tool for complete installation.This design enables the installation and maintenance costs to be significantly reduced, as the supply lines can be connected free of tension in the shortest amount of time possible. Disassembly is also possible without the need for lots of tools, leading to less machine downtime and unequivocal cost advantages for the operator.The “tense installation” of the rotating unions is constructively avoided and the life span of the unions increases in the same way as the energy efficiency, because the pressure springs, for example, are situated outside of the medium. This is how the rollers or calender are kept constantly supplied with the correct volume flow rate to the heat transfer media by the rotating union. Loss of pressure and heat output no longer occurs.Depending on the series used, such hot media rotating unions display a stable bearing design and a secondary seal in the form of a membrane, therefore there is no relative motion at the sealing point. Moreover, for increased machine safety, versions with housing and rotor locking rings and additional snap rings can be ordered as an “emergency safety catch”.

Conclusion:

The expertise of the engineers working for machine manufacturers and manufacturers of high-quality rotating unions consequently leads to further developments and the constant discovery of new potential, with which further goals for the future can be reached.

Investment in high-quality machines made of high-quality assemblies and components, designed with the most recent developments in mind, pays off in no time

美国Deublin杜博林旋转接头轮胎橡胶工业应用典型设备:

Banburv mixers 单螺杆密炼机

Calenders 压延机

Calenders/insertmills 压延机/插入压延

Extrudrs-Tubers 胶条挤出机

帘布、胶条压合机

Lab挤出机

Lab Mills

Lab密炼机

Mills /Warning Types

后压延辊

预压延辊

胎压

水蒸汽热油用塑料工业用旋转组件:旋转接头允许在固定机器的一部分和另一个旋转之间进行水密密封。Deublin专门为通常的蒸汽、水或热油应用设计了接头。124在塑料工业中很常见。DEUBLIN接头的自支撑设计非常适合没有外部安装表面的开放式传动机器。

Deubin杜博林橡胶及塑料行业旋转接头:

|

|

155-122-152

DN 15

rotor 1/2'' BSP a izquierdas

1/2'' BSP

3500 rpm

50 bar

Temp. Max.60oC |

255-269-284

DN 20

rotor3/4''BSP à direita

3/4'' BSP

3500 rpm

0 bar

Temp. Max.60oC |

|

|

| 255-269-285

DN 20

rotor3/4'' BSP

3/4'' BSP

3500 rpm

50 bar

Temp. Max.60oC |

155-122-151 Duplo

155-122-151 Duplo

DN 15

rotor 1/2'' BSP

1/2'' BSP

B3/8'' BSP

3500 rpm

Press?o Máx.50 bar

Temp. Max.120oC |

|

|

155-122-152 Duplo

DN 15

rotor 1/2'' BSP à inversa

1/2'' BSP

B3/8'' BSP

3500 rpm

Press?o Máx.50 bar

Temp. Max.120oC |

55-655-094

DN 10

rotor 3/8''

3/8'' BSP

3500 rpm

Máx. 50 bar

Temp. Max.120oC |

|

|

| 55-655-095

DN 10

Rosca rotor 3/8''

3/8'' BSP

Máx.3500 rpm

Press?o Máx.50 bar

Temp. Max. |

55-655-095121 DUPLO

DN 10

rotor 3/8''

3/8'' BSP

B1/4'' BSP

Máx.3500 rpm

Máx.50 bar

Temp. Max.120oC |

|

|

| 255-269-284351 DUPLO

DN 20

rotor 3/4''BSP

3/4'' BSP

B1/2'' BSP

Máx.3500 rpm

Press?o Máx.50 bar

Temp. Max.120oC |

255-269-285 DUPLO

DN 20

rotor 3/4'' BSP

3/4'' BSP

B1/2'' BSP

3500 rpm

50 bar

Temp. Max.120oC |

|

|

| 355-204-222

DN 25

rotor 1'' BSP

1'' BSP

3000 rpm

50 bar

Temp. Max.120oC |

355-204-223

DN 25

rotor 1'' BSP

1'' BSP

3000 rpm

50 bar

Temp. Max.120oC |

|

|

| 355-204-222912 DUPLO

DN 25, ELBOW 350-912

rotor 1'' BSP

1'' BSP

1/2'' BSP

3000 rpm

50 bar

Temp. Max.120oC |

355-204-223912 DUPLO

DN 25

rotor 1'' BSP

1'' BSP

B1/2'' BSP

ELBOW 350-912

3000 rpm

50 bar

Temp. Max.120oC |

|

|

| 525-301-054

DN 32

rotor 1 1/4'' BSP à direita

1 1/4'' BSP

2500 rpm

50 bar

Temp. Max.120oC |

525-301-055

DN 32

1/4'' BSP à inversa

1 1/4'' BSP

2500 rpm

50 bar

Temp. Max.120oC |

|

|

| 525-301-054594 DUPLO

DN 32

Rrotor 1 1/4'' BSP

1 1/4'' BSP

B3/4'' BSP

ELBOW 525-594

2500 rpm

50 bar

Temp. Max.120oC |

525-301-055594 DUPLO

DN 32

rotor 1 1/4'' BSP

1 1/4'' BSP

B3/4'' BSP

ELBOW 525-594

2500 rpm

50 bar

Temp. Max.120oC |

|

|

| 555-385-198

DN 40

rotor 1 1/2'' BSP

1 1/2 BSP

2500 rpm

50 bar

Temp. Max.120oC |

555-385-199

DN 40

rotor 1 1/2'' BSP

1 1/2 BSP

2500 rpm

50 bar

Temp. Max.120oC |

|

|

555-385-198171 DUPLO

DN 40

rotor 1 1/2'' BSP

1 1/4'' BSP

B3/4'' BSP

Elbow 451-171

2500 rpm

50 bar

Temp. Max.120oC |

555-385-19971 DUPLO

DN 40

rotor 1 1/2'' BSP

1 1/2 BSP

B3/4'' BSP

elbow 451-171

2500 rpm

50 bar

Temp. Max.120oC |

|

|

| 655-527-124

DN 50

rotor 2'' BSP

2'' BSP

750 rpm

50 bar

Temp. Max.120oC |

655-527-125

DN 50

rotor 2'' BSP

2'' BSP

750 rpm

50 bar

Temp. Max.120oC |

|

|

| 655-527-124534 DUPLO

DN 50

rotor 2'' BSP

2'' BSP

B1 1/4'' BSP

Elbow 450-534

750 rpm

50 bar

Temp. Max.120oC |

655-527-125534 DUPLO

DN 50

rotor 2'' BSP

2'' BSP

B1 1/4'' BSP

elbow 450-534

750 rpm

50 bar

Temp. Max.120oC |

|

|

1205-000-151

1/2'' BSP

3500 rpm

Press?o Máx.10 bar air / 70 bar hydraulic

Temp. Max.120oC |

1205-000-152

DN15

rotor 1/2

1/2'' NPT

3500 rpm

10 bar air / 70 bar hydraulic

Temp. Max.120oC |

|

|

1115-000-200

UNION M16X2 RH

Item #: 1115-000-200

Rotor: M16x2 Metric RH |

1115-000-205

UNION 3/8 BSP RH

Item #: 1115-000-205

Rotor: G3/8" BSP RH |

|

|

250-094-284

UNION 3/4 BSP RH

Item #: 250-094-284

Rotor: G3/4" BSP RH |

250-094-285

UNION 3/4 BSP LH

Item #: 250-094-285

Rotor: G3/4" BSP LH |

|

|

355-021-222

UNION CG/C 1 BSP RH

Item #: 355-021-222

Rotor: G1" BSP RH |

355-021-223

UNION CG/C 1 BSP LH

Item #: 355-021-223

Rotor: G1" BSP LH |

|

|

452-000-198

UNION 1 1/2 BSP RH

Item #: 452-000-198

Rotor: G1 1/2" BSP RH

|

452-000-199

UNION 1 1/2 BSP LH

Item #: 452-000-199

Rotor: G1 1/2" BSP LH |

【信德迈科技(北京)有限公司是美国Deublin杜博林旋转接头正式授权十年北方地区代理商】 美国deublin公司成立于1945年。是世界上专业生产各种精密气体、液压及冷却液旋转接头、蒸汽旋转接头、冶金旋转接头和各类内部膨胀管的厂家。产品选型资料及更详细产品介绍请点击:http://www.cnmec.net/pic.html

美国Deublin杜博林旋转接头授权

代理商联系方式:

信德迈科技(北京)有限公司 CNMEC Technology Company

地址:北京市朝阳区望京SOHO-T1-C座2115室

邮编:100102

*Tel: 010-84282935 | * Fax: 010-84288762

*手机:139 1096 2635

*电子邮件: sales@cnmec.biz

主页:http://www.cnmec.net/pic.html

公司网址:www.cnmec.biz

联系方式:sales@cnmec.biz

信德迈公司公众账号:xindemai

|