|

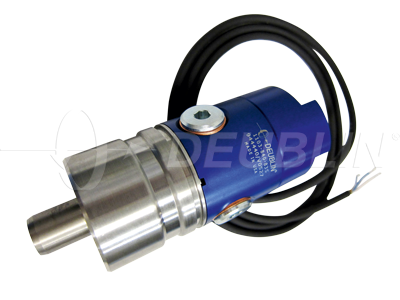

Deublin用于带集成主轴保护警报系统的主轴保护旋转接头

带传感器自动感应泄漏检测报警系统的主轴保护旋转接头 - 检测冷却液问题并允许快速关闭机器

SpindleShield Series Unions with Integrated Alert System for Spindle Protection

Deublin SpindleShield Unions

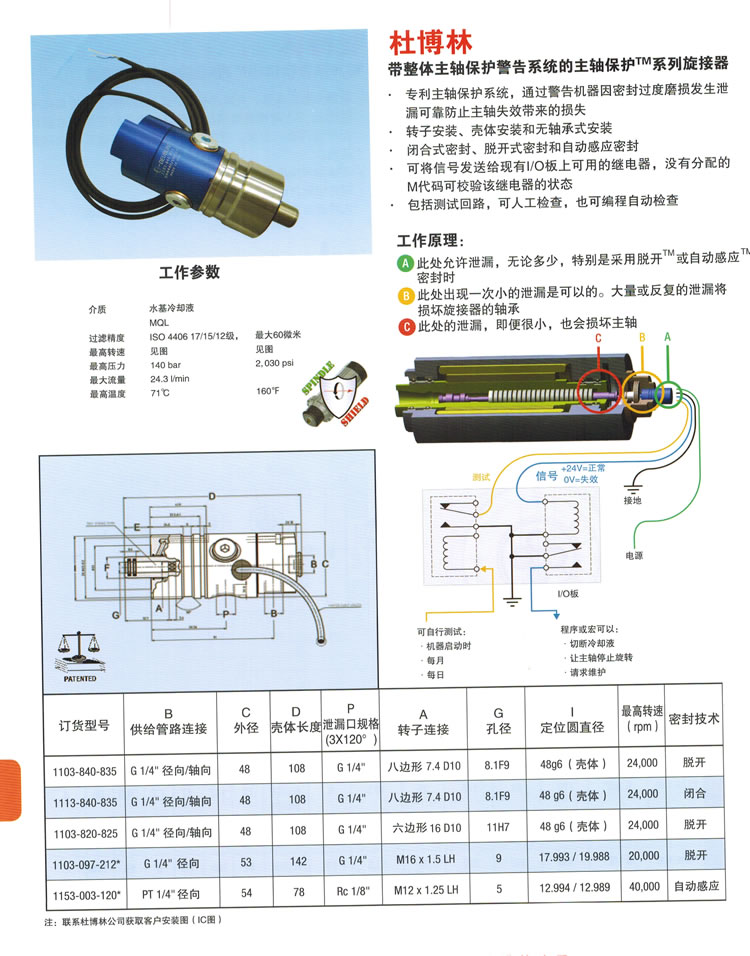

带整体主轴保护警告系统的主轴保护系列旋接器

杜博林公司宣布SpindleShield技术用于先进的数控机床。带SpindleShield的Deublin冷却液接头采用独特的正在申请专利的电子泄漏检测系统,检测冷却液问题并允许快速关闭机器。DEUBLIN Company announces SpindleShield technology for use with the most sophisticated CNC machines. DEUBLIN coolant unions with SpindleShield employ a unique patent-pending electronic leak detection system that detects coolant problems and allows for rapid machine shutdown.

产品重要特性

-

专利主轴保护系统,通过警告机器因密封过度磨损发生泄漏可靠防止主轴失效带来的损失

- 转子安装、壳体安装和无轴承式安装

- 闭合式密封、脱开式密封和自动感应密封

- 可将信号发送给现有/O板上可用的继电器,没有分配白

- M代码可校验该继电器的状态

- 包括测试回路,可人工检查,也可编程自动检查

Deublin SpindleShieldTM Series Unions with Integrated Alert System for Spindle Protection

Deublin SpindleShield Unions PDF Catalog

Deublin DBL_SpindleShield2_LR-1.jpg

带有贯穿冷却液主轴的加工中心需要冷却液管接头通过切削表面的刀具在高压下输送冷却液。对于空气、MQL或冷却液等多介质的干运转循环或加工操作,Deublin提供带有专利弹出和专利申请中的Autosense的冷却液接头,这是一种在没有冷却液的情况下分离密封件的技术,并允许无限的干运转或多媒体功能。在从一种模式到另一种模式的每一个循环中,都会有少量的冷却液溢出,必须收集并排空。如果未检测到过度泄漏,可能会通过主轴密封件泄漏,终污染和损坏主轴轴承。Machining centers with through-coolant spindles require coolant unions to deliver coolant at high pressures through the cutting tool at the cutting surface. For dry running cycles or machining operations with multi-media such as air, MQL or coolant, DEUBLIN offers coolant unions with patented Pop-Off and patent-pending AutoSense a technology that separates the seals in the absence of coolant and allow indefinite dry run or multi-media capabilities. During each cycle from one mode to the other, a minute amount of coolant spills out, which must be collected and drained. Excessive leakage, if not detected, may leak past the spindle seals and eventually contaminate and damage the spindle bearings.

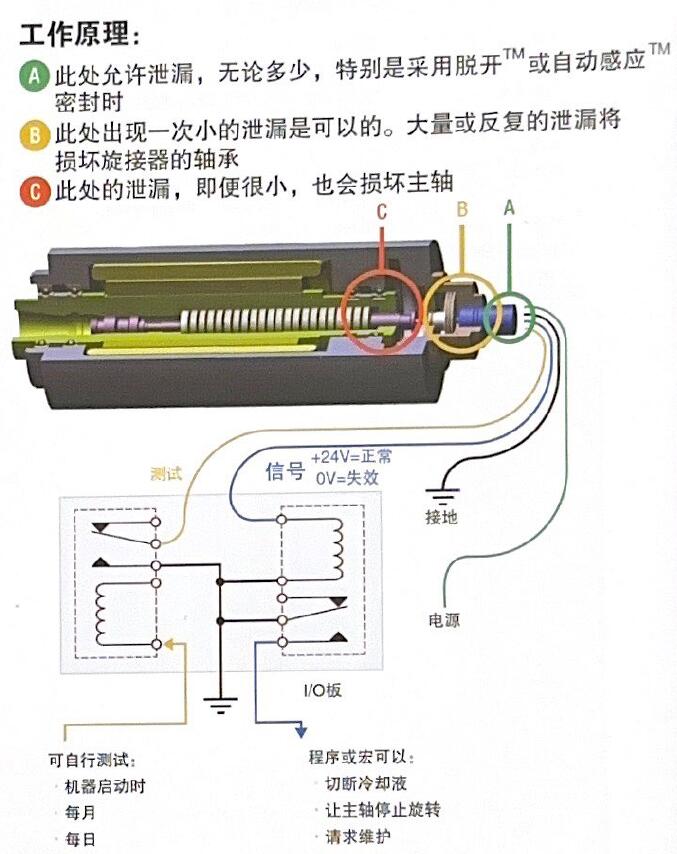

工作原理

- A 此处允许泄漏,无论多少,特别是采用脱开TM或自动感应

- B 密封时此处出现一次小的泄漏是可以的。大量或反复的泄漏将损坏旋接器的轴承

- C 此处的泄漏,即便很小,也会损坏主轴

SpindleShield protects the spindle and prevents replacement of spindle bearings by allowing rapid, automatic shutdown of machines. The combination of remote diagnostics and a positive leak detection system virtually eliminate unnecessary preventative maintenance and costly spindle repair. This technology can be easily integrated into any standard system bus.

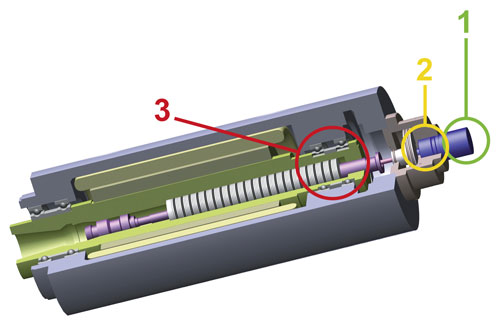

工作原理:

1此处允许泄漏,无论多少,特别是采用脱开M或自动感密封时

2此处出现一次小的泄漏是可以的。大量或反复的泄漏将损坏旋接器的轴承

3 此处的泄漏,即便很小,也会损坏主轴

Deublin带整体主轴保护警告系统德主轴保护系列旋转接头

杜博林带整体主轴保护警告系统德主轴保护系列旋转接头

Deublin SpindleShield? Unions

Deublin公司宣布SpindleShield?技术用于先进的数控机床。带SpindleShield?的Deublin冷却液接头采用独特的正在申请专利的电子泄漏检测系统,检测冷却液问题并允许快速关闭机器。DEUBLIN Company announces SpindleShield? technology for use with the most sophisticated CNC machines. DEUBLIN coolant unions with SpindleShield? employ a unique patent-pending electronic leak detection system that detects coolant problems and allows for rapid machine shutdown.

Deublin带整体主轴保护警告系统德主轴保护系列旋转接头

带有贯穿冷却液主轴的加工中心需要冷却液管接头通过切削表面的刀具在高压下输送冷却液。对于空气、MQL或冷却液等多介质的干运转循环或机械加工操作,Deublin提供带有专利Pop-off?和专利申请中的Autosense?的冷却液接头,这是一种在没有冷却液的情况下分离密封件的技术,并允许不确定的干运转或多介质能力。s.在从一种模式到另一种模式的每一个循环中,都会有少量的冷却液溢出,必须收集并排放。如果未检测到过度泄漏,可能会通过主轴密封件泄漏,终污染和损坏主轴轴承。Machining centers with through-coolant spindles require coolant unions to deliver coolant at high pressures through the cutting tool at the cutting surface. For dry running cycles or machining operations with multi-media such as air, MQL or coolant, DEUBLIN offers coolant unions with patented Pop-Off? and patent-pending AutoSense? a technology that separates the seals in the absence of coolant and allow indefinite dry run or multi-media capabilities. During each cycle from one mode to the other, a minute amount of coolant spills out, which must be collected and drained. Excessive leakage, if not detected, may leak past the spindle seals and eventually contaminate and damage the spindle bearings.

SpindleShield?通过允许机器快速自动停机来保护主轴并防止更换主轴轴承。远程诊断和积极检漏系统的结合实际上消除了不必要的预防性维护和昂贵的主轴维修。这种技术可以很容易地集成到任何标准系统总线中。SpindleShield? protects the spindle and prevents replacement of spindle bearings by allowing rapid, automatic shutdown of machines. The combination of remote diagnostics and a positive leak detection system virtually eliminate unnecessary preventative maintenance and costly spindle repair. This technology can be easily integrated into any standard system bus.

DEUBLIN SpindleShield/ Machine Tool Industry

Thanks to the patented SpindleShield technology in combination with Pop-Off and AutoSense rotat-ing unions, this system is able to avoid damage to the spindle and downtimes of the machining centre and to simultaneously increase the productivity. If Coolant leaks occur which are not due to normal operation, the system will alert the machine operator.

The SpindleShield technology can be retrofitted to all processing centres.

SpindleShield Technologie

Usual leakage monitoring only checks for the existence of liquid in the area of the drain lines. To make this work, the system must be able to distinguish between “real leakage” and “function-inherent” leak-age. So error messages are pre-programmed no matter whether an opening or permanently closed technology is concerned. However, as mechanical seal faces always require a small quantity of “leak-age” as lubrication – which increases the service life – this concept results in ambiguous operating conditions.

SpindleShield Drehdurchführung

SpindleShield, however, checks the occurring leakage which has entered the bearings of the rotating union; meaning that they are continuously monitored as a load bearing element of the machine part.

SpindleShield “knows” e.g. that minor or major leakage quantities directly at the sealing surfaces at Pop-Off or AutoSense rotating unions are normal while repeatedly occurring Coolant leakage in the area of the bearings may damage them and is thus definitely a warning signal. This is important as leakage entering the spindle through the bearings of the rotating union can cause considerable damage to the spindle bearings and the electric motor.

Kontrollger?t

Apart from issuing the warning message, SpindleShield is able to communicate with the machine control via i/o board and trigger program steps/macros, such as stop Coolant supply, stop spindle or call the maintenance engineer.

In addition, the circuit set-up also allows for the identification of damage at the sensor lines and the processing and notification of this information.

Machine downtime, spindle damage and the consequences may quickly add up to considerable costs. Investing in the SpindleShield technology helps to reduce these costs to a minimum!

1103-840-835 G 1/4" Radial/Axial 48 108 G 1/4" Octagon 7.4 D10 8.1F9 48g6 (housing) 24,000 Pop-Off

1113-840-835 G 1/4" Radial/Axial 48 108 G 1/4" Octagon 7.4 D10 8.1F9 48 g6 (housing) 24,000 Closed

1103-820-825 G 1/4" Radial/Axial 48 108 G 1/4" Hexagon 16 D10 11H7 48 g6 (housing) 24,000 Pop-Off

1103-097-212* G 1/4" Radial 53 142 G 1/4" M16 x 1.5 LH 9 17.993 / 19.988 20,000 Pop-Off

1153-003-120* PT 1/4" Radial

- Download PDF Catalog

DEUBLIN SpindleShield Unions for CNC Machining Centers

Deublin SpindleShield Unions SpindleShield Alert System

1103 Series Bore-Mounted Pop-Off with SpindleShield Alert System

1103 SOS SpindleShield Operation System to Retrofit Existing Machines

DEUBLIN SpindleShield Unions for CNC Machining Centres

订货型号 |

B 供给管路连接 |

C外径 |

D壳体长度 |

P泄露口规格

3X120° |

A转子连接 |

G孔径 |

I 定位圆直径 |

最高转身rpm |

密封技术 |

1103-840-835

|

G1/4"径向/轴向 |

48 |

108 |

G 1/4" |

八边形7.4D10

|

8.1F9

|

48g6(壳体) |

24000 |

脱开 |

1113-840-835 |

G1/4”径向/轴向 |

48 |

108 |

G 1/4" |

八边形 7.4D10 |

8.1F9 |

48g6(壳体) |

24000 |

闭合 |

1103-820-825 |

G1/4"径向/轴向 |

48 |

108 |

G 1/4" |

六边形16D10 |

11H7 |

48g6(壳体) |

24000 |

脱开 |

1103-097-212* |

G 1/4”径向 |

53 |

142 |

G 1/4" |

M16X1.5LH |

9 |

17.993 / 19.988 |

20000 |

脱开 |

1153-003-120 |

PT 1/4"径向 |

53 |

78 |

Rc 1/8" |

M12 x 1.25 LH |

5 |

|

40000 |

自动感应 |

| 1103-342-730 |

|

|

|

|

|

|

|

|

|

|